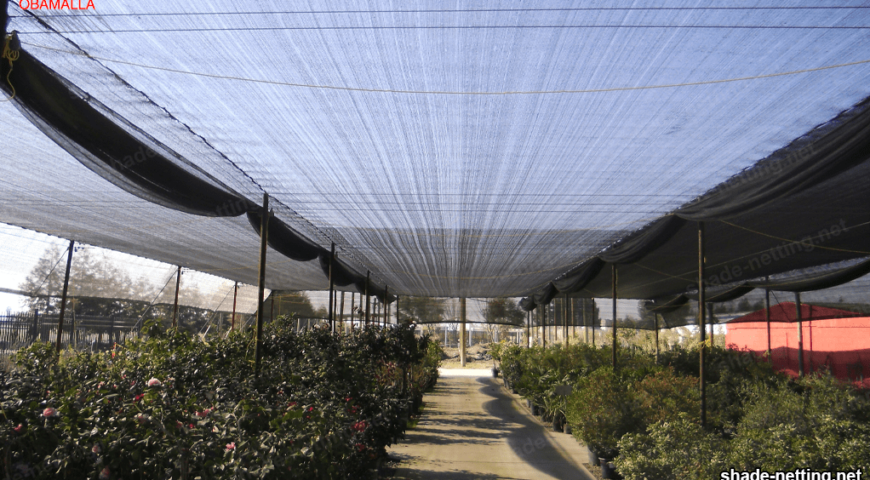

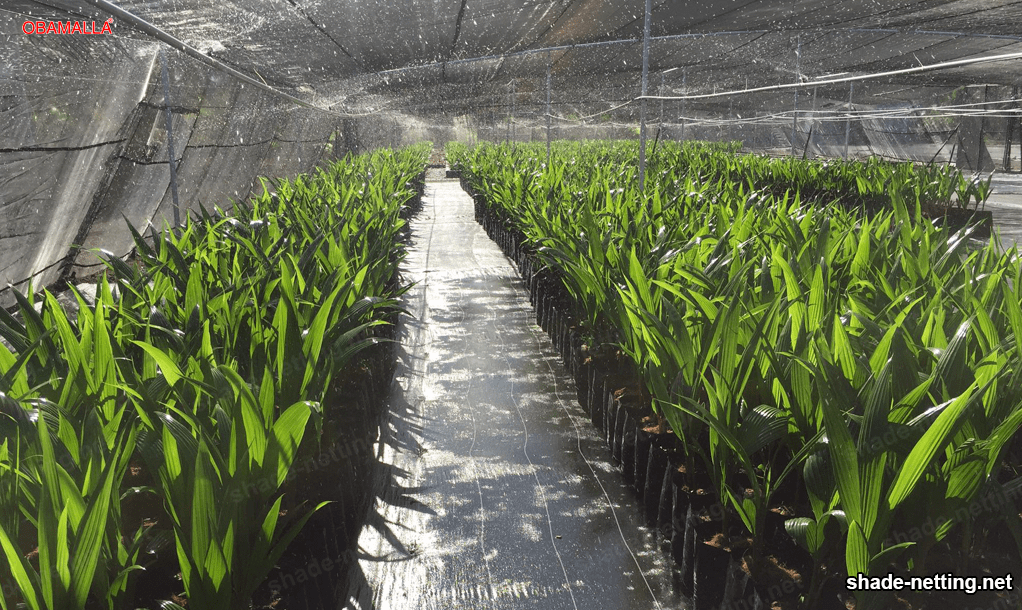

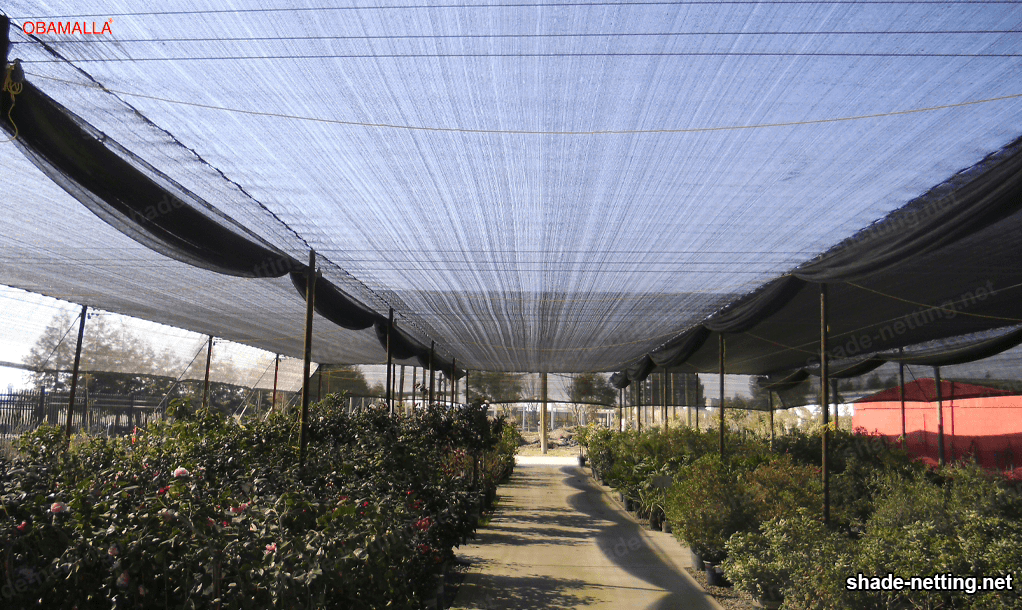

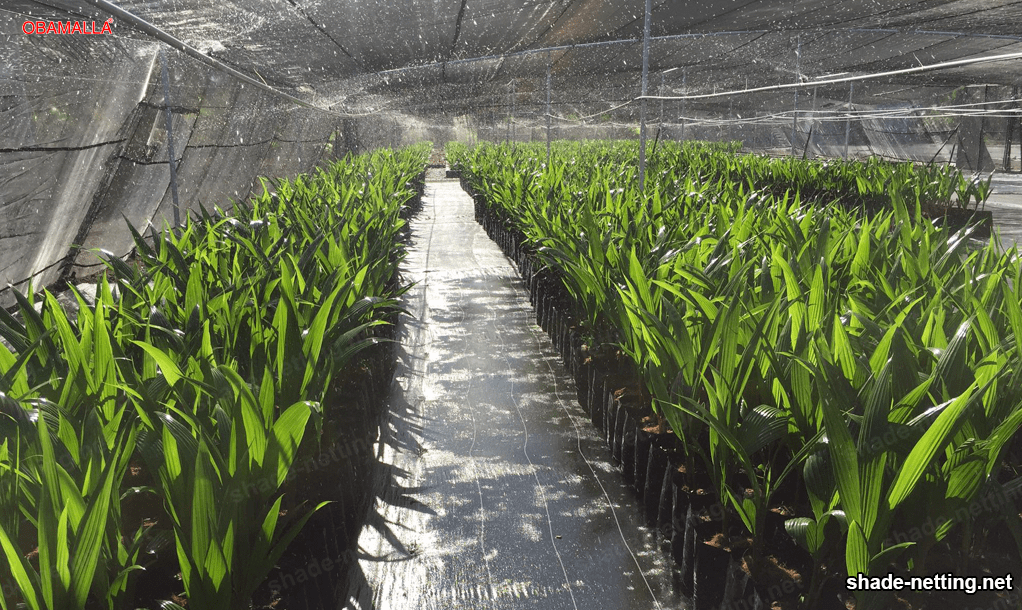

Shade netting is a good choice for cutting off direct sunlight, preserving privacy and maintaining a pleasant environment.

While it is a durable material, it is also vulnerable to damage from exposure to the elements, as well as general wear and tear.

While you can discard and replace shade netting, it is crucial to follow good maintenance practices to enhance its durability and keep it in top condition.

First, homeowners or business owners should inspect shade netting at least once a year for damage, tears or other problems. A properly installed, tight-fitting lattice can minimize the shade screen’s exposure to the elements and improve durability. If the shade netting has snagged on a nearby tree or plant, it is necessary to choose a shelter for the area in question. This can prevent excessive exposure to direct sunlight, wind and storms that can deteriorate the shade netting in the long term.

When it is time to clean the shade netting, a soft brush is sufficient to remove dirt and dust. Avoid washing the shade netting with soap or detergents, as these can be too abrasive and damage the material. Instead, use water and a cloth or a low-pressure hose and a soft sponge to easily remove dust, moisture residue, and laulescence. Pay particular attention to heavily soiled areas, targeting them with water pressure to remove all dirt without damaging the mesh.

Finally, the shade mesh can be bleached to make it look like new. A fabric safe bleach will not only remove stains and dirt, but will also disinfect from the outside.

After bleaching or washing the shade netting, leave it to air dry and apply a UV protectant to resist sun damage.

While it is true that the maintenance for a shade screen is fairly low maintenance, it is important to carry it out to ensure that it lasts for a long time. The following is a guide to proper shade netting maintenance. It is important to clean the shade screen regularly. It is also advisable to avoid prolonged exposure to the sun to prevent discoloration of the screen.

If you detect any damage to the mesh, repair it immediately to prevent further deterioration. Additionally, monitor the edges of the shade netting to ensure they are tight. If the edges are loose, secure them with a nail or screw.

Another important thing to consider is the support structure of the shade screen. Regularly inspect this structure to ensure it is in good condition and has no weak areas. Physically inspect it to determine its condition.

Proper maintenance of the shade netting is important to ensure that it continues to perform the function for which it was designed.

How to avoid damage and rips to shade netting

- It is essential to have a quality shade netting. Whether purchased in a commercial store or handmade, make sure that the material used in its manufacture is resistant to wear and tear caused by weathering. It is also advisable to opt for raw materials from reliable sources to ensure the strength and quality of the shade netting.

- Once the shade netting has been purchased, it is advisable to place it in a place protected from the weather. This means avoiding exposure to direct sunlight or direct rain and wind for a prolonged period of time. If exposure is unavoidable, ensure the installation of an adequate mesh stabilization system to prevent unnecessary stresses that may cause tears. Additionally, regularly clean the shade netting for optimal maintenance. This will help reduce wear caused by weathering by removing the accumulation of particles and loose elements that can lead to tearing and loss of strength.

- Another aspect to consider is to perform a regular inspection to check the condition of the shade netting. This inspection should include an examination of the fasteners to check that the mesh is tight, without unnecessary pressure. It is also advisable to check the mesh elements for cuts or tears, and repair where necessary.

- It is important to emphasize the importance of the proper placement of the shade netting when it is necessary to relocate it. In these cases, it is advisable to have a team specialized in the installation and movement of the mesh to ensure that no damage occurs as a result of handling.